Packaging plays a crucial role in branding, protection, and customer experience. However, for startups and established businesses, understanding packaging costs is essential for budget planning. This guide will help brands make informed decisions about packaging expenses, ensuring they get the best value without compromising quality.

What Affects The Costing Budget?

There are several factors that affect the budget when considering packaging costs. We have made a list of factors that matter the most in the packaging budget, such as:

- Material selection

- Artwork & Printing Options

- Box Styles/Structural Integrity

- Additional Add-ons & Finishing Options

- Manufacturing cost

A thorough understanding of these elements can help businesses plan and allocate resources more effectively, ensuring cost-effective packaging decisions.

Material selection

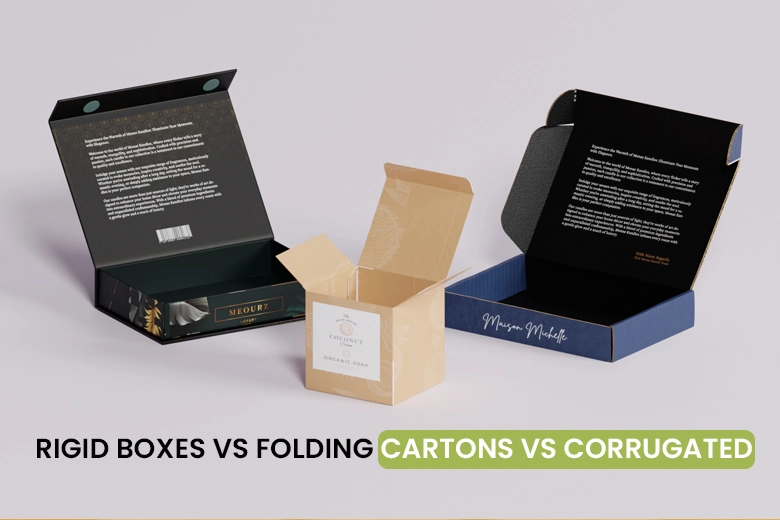

One of the first factors that affects the packaging cost is the material selection. When selecting packaging materials, businesses must consider their durability, sustainability, aesthetics, and cost. Below are some commonly used materials for custom packaging & boxes:

- Kraft Paper: It’s an affordable, eco-friendly, and sturdy option for basic packaging needs like bags and boxes. This type of material is ideal for brands with a rustic or organic image.

- Corrugated Cardboard: This type of material is lightweight, strong, and cost-effective for bulk shipping and protective packaging for larger items.

- Paperboard: A thinner and smoother material that is a cost-effective option for retail packaging like food and cosmetics, offering a premium look.

- Rigid Stock: This type of material is made from thick cardboard and specialty paper. Boxes made of rigid stock are perfect for high-end product packaging like jewelry, offering custom designs and premium finishes.

Artwork & Printing Options

Artwork & printing options can highly influence the overall packaging costs. The quality of the print you choose affects your pricing. Especially those that require special inks or coatings. Full-color printing and custom graphics can increase the price due to the complexity and materials involved.

Packaging designs that involve multiple colors, complex details, or custom logos require specialized printing techniques. This contributes to higher costs. However, with careful planning, businesses can streamline artwork design and printing options to align with their budget while still producing visually appealing packaging that reinforces their brand identity.

Box Inserts

Box inserts add functional value but also increase packaging costs. Custom inserts can be found in various materials, including cardboard and foam. Using these can increase the packaging cost. They are somewhat essential for some products like perfumes, jewels, and other luxury products but not for all. If your product can be stored without box inserts, it is recommended not to use them to avoid an increase in pricing!

Box Styles/Structural Integrity

The box style and its structural integrity can also impact pricing. A custom shape or box style may offer a unique presentation and protection, but remember that they can add expense to your pricing as well. Using stronger materials and designs can ensure durability but comes at a higher cost.

Additional Add-ons & Finishing Options

Add-ons like coatings, die-cuts, or premium finishes (e.g., foil stamping) enhance packaging but increase costs. These options require additional materials and production time, raising expenses. Evaluate if these features are necessary for branding or if a simpler design can help manage costs without sacrificing appeal.

Manufacturing Cost

Manufacturing costs include labor, machinery, and energy, varying by production scale and complexity. Mass production reduces per-unit costs, but smaller runs are more expensive.

The type of packaging materials and processes involved also affect overall manufacturing expenses. Understanding these costs can help businesses to optimize their packaging strategies while managing budgets effectively.

Below is the breakdown of the cost of packaging materials with finishing options:

| Type Of Material | Standard Size (in inches) | Estimated Price |

| Corrugated Cardboard | 8 x 8 x 8 | $3 to $4.50 (depending on finishes) |

| Kraft Paper | 6 x 6 x 6 | $2 to $3.75 (depending on finishes) |

| Rigid Stock | 8 x 8 x 4 | $10 to $15 (depending on finishes) |

Fixed & Variable Costs

Packaging costs can be broken down into fixed and variable costs.

Let’s take a deeper look at it!

Fixed Cost

Fixed costs remain constant regardless of the quantity produced, such as setup fees for printing or the cost of molds for custom packaging. These costs don’t change with the number of units you produce, making them predictable.

Variable Cost

Variable costs can fluctuate based on production volume. These can include materials, labor, and shipping costs, which vary depending on how many units are produced. Understanding the distinction between fixed and variable costs helps businesses plan for both short-term and long-term packaging expenses.

How to Calculate Cost?

To calculate packaging costs, follow these steps:

- Determine raw material costs: This includes the cost of the materials used for your packaging, including any customization.

- Add labor costs: Consider the manufacturing and labor expenses associated with producing the packaging.

- Include overhead costs: Don’t forget additional expenses like shipping and storage.

- Factor in printing and finishing costs: This covers any costs for artwork, printing, and finishing touches like coatings or embossing.

- Divide by units: Once you have all the costs, divide the total by the number of units to get the cost per unit.

Tracking these factors helps businesses understand their packaging expenses and find ways to save without compromising quality.

Frequently Asked Questions?

Which material is the most expensive?

Rigid stock is the most expensive material that is used to pack high-end items. This material offers enhanced durability and sustainability, but it also increases the overall packaging cost.

What is the average packaging cost?

The average packaging cost can vary greatly depending on the type of packaging, materials, and customization options you select.

Are kraft paper bags expensive?

Kraft paper bags are generally not expensive compared to other packaging options, but prices can rise depending on size, custom printing, and the weight of the paper.

How do I lower the price if I don’t want to order in bulk?

If bulk ordering is not an option, consider optimizing your packaging choices by simplifying the design, selecting cost-effective materials, or reducing unnecessary add-ons. By doing so, you can lower the cost of your packaging.

What is the formula for price per unit?

You can calculate your packaging cost per unit by using the following formula: (Total Packaging Cost) / (Number of Units).

How Much Does Cardboard Packaging Cost?

Cardboard packaging costs typically range from $2 to $6.75 per box, depending on factors like box style, printing options, and finishing touches. Custom designs, premium coatings, and additional print sides can increase the price.