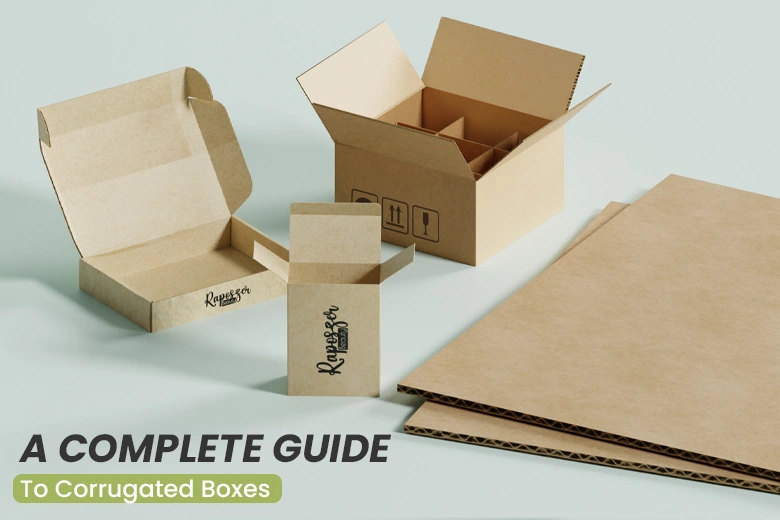

Corrugated boxes are the most popular packaging choice preferred by businesses across various industries. From simple retail boxes to delivering products, many brands rely on corrugated for their packaging needs. Moreover, many people still think that cardboard and corrugated are the same. Well, they are not, and they even have some differences. To get a better understanding, let’s explore everything you should know about corrugated boxes—from A to Z!

What Are Corrugated Boxes?

First things first, let’s define the meaning of corrugated boxes. What is a corrugated box? A sturdy corrugated box is made of corrugated cardboard. Thanks to its durability and flexibility, many businesses in North America rely on corrugated boxes to ship their products.

So, What Is Corrugated Cardboard?

Corrugated cardboard is made from paper pulp, mainly composed of timber and recycled wood chips. Unlike single-sheet cardboard, corrugated cardboard consists of three layers: A fluted filler (corrugated medium) sandwiched between two flat liner boards.

Corrugated Vs Cardboard Packaging

Cardboard is essentially a thin, pasteboard material made from heavy paper pulp or paper stock. On the other hand, as mentioned above, corrugated cardboard consists of three layers — a fluted filler (corrugated medium) sandwiched by flat liner boards. These flutes resist bending and pressure, offering high resistance to shocks, moisture, and temperature changes.

When used in the right circumstances, both cardboard and corrugated boxes can be effective packaging options. Cardboard boxes are lightweight, sturdy, yet protective. However, despite the many types of cardboard boxes, corrugated boxes remain the favorite option for many businesses, especially for shipping their products.

What Are the Liner Materials of Corrugated Boxes?

The liner materials of corrugated boxes are typically made from containerboard (a type of paperboard). Do note that the outside liner of your boxes can directly impact the strength, cost, and sustainability of the boxes.

Here are the two main types of liner materials available for your choice.

- Kraft Paper Liners

Made from virgin chemical pulp fiber, kraft is renowned for its exceptional durability and strength, making it an ideal choice for enhanced product protection. Plus, Kraft offers a better, smoother surface for printing.

- Test Paper Liners

Made from recycled fiber, test paper is primarily used as inner liners, as it is less durable than kraft paper.

In addition to the primary liner options above, specialized liners are also available, such as Barrier Liners. The liners consist of two sheets of kraft laminated with polyethylene (PE), which provide exceptional moisture protection, making them perfect for packaging food products or electronics.

What Is a Flute in a Corrugated Box?

Flutes in a corrugated box will appear as the wavy lines sandwiched between two flat layers of linerboard. These flutes are the ones that differentiate corrugated boxes from cardboard, as they make the boxes sturdier to fight against crushing or damage during transit. There are five different flutes, each with its unique characteristics and features.

Let’s break it down!

- A-Flute (33 flutes per linear foot) is the thickest corrugated flute at ¼ inch thick. Its thickness offers lots of protection and makes it a good option for fragile items.

- B-Flute (47 flutes per linear foot) is ⅛ inch thick. It’s deceptively strong and widespread for die-cut corrugated box designs.

- C-Flute (39 flutes per linear foot) is 3/16 inch thick. This is the one you’re probably the most familiar with, since it’s the best option for shipping boxes.

- E-Flute (90 flutes per linear foot) is only 1/16” thick. It’s sometimes used as an alternative to paperboard for folding carton boxes.

- F-Flute (125 flutes per linear foot) is 1/32” thick and is among the thinnest of the flute grades, which also offer a smooth surface for printing.

What Are the Different Walls in Corrugated Boxes?

In addition to the flute grades and liners, corrugated boxes are available in various wall thicknesses.

Depending on the type of product you need to pack inside, you can choose the right kind of wall from the options below:

- Linerboard: A flat sheet with two layers of paper and fiber, where one layer consists of paper and recycled fiber.

- Single Face: It’s a single sheet of liner attached to one sheet of corrugated flute, perfect for shipping breakable items and protecting delicate products.

- Single Wall: It consists of two linerboard sheets with one fluted fiberboard glued in between.

- Double Wall: Three linerboard sheets with two fluted fiberboard glued in between.

- Triple Wall: It consists of four linerboard sheets with three fluted fiberboard glued in between.

Do you have specific products that need to be packed and delivered? How about mixing the flutes? Depending on your product’s and packaging needs, you can combine the different flutes and walls.

For example:

- AC Flute

As the name suggests, it’s a combination of A and C flute grades, resulting in excellent product protection during shipping and handling.

- BC Flute

The combination of B and C flutes creates durable shipping boxes that perform well during transit.

- EB Flute

If you need corrugated boxes that provide a high-quality printing surface while protecting your products perfectly, the EB flute type is the best option.

How to Ensure the Strength of a Corrugated Box?

Product safety is the most important point when shipping products. Therefore, several standard tests are used to ensure the strength of a corrugated box.

What are they?

ECT (Edge Crush Test)

The ECT test is compulsory if you need to stack corrugated boxes. The test aims to measure the compression strength of the board’s edges, ensuring the box withstands stacking loads and vertical pressure.

Mullen Test (Burst Test)

From the name, we understand that the Mullen Test aims to measure the resistance of your box to puncture or bursting.

FCT (Flat Crush Test)

The FCT test examines the resistance of the corrugated board to crushing, which determines the box’s ability to withstand impact and compression.

All the standard tests above are conducted to guarantee that your corrugated boxes can withstand various pressures during shipping and handling.

Understand the Box Maker’s Certificate

After undergoing the tests and customization, a Box Maker’s Certificate (BMC) is affixed to the outside bottom flap. The stamp identifies the material and certifies the results of the Mullen Bursting Test or the Edge Crush Test. This symbol identifies the manufacturer and serves as a symbol of compliance.

What Are the Benefits of Using Corrugated Boxes?

No doubt, corrugated cardboard is a sturdy and practical material that offers numerous benefits.

Here are some promising benefits your business can get from using corrugated packaging boxes.

- Better Product Protection: Corrugated offers superior protection compared to other material types.

- Lightweight: The lightweight nature of corrugated cardboard makes it easier to handle during storage and transportation.

- Customizable: The material can be tailored to meet your branding needs.

- Sustainability: Since corrugated cardboard is made from recycled fibers, it is easy to recycle the boxes, thereby reducing packaging waste and promoting sustainability.

- Cost Effectiveness: Corrugated material is readily available and more flexible than other options. Moreover, its lightweight nature also helps minimize shipping costs.

The Disadvantages of Using Corrugated Boxes

Although preferable for retail boxes and e-commerce packaging, corrugated boxes have some disadvantages.

- Moisture & Weather Sensitivity: The paper pulp material makes corrugated boxes vulnerable to moisture and water damage.

- UV Exposure: Exposure to UV light can cause the printed designs and logos to fade.

- Limited Reusability: Corrugated boxes are often discarded after a single use.

Despite the drawbacks mentioned above, corrugated boxes remain the most effective secondary packaging option, providing additional protection for your products during transit.

The Various Corrugated Box Style Options

Many businesses choose custom corrugated boxes as they meet different purposes and expectations. Hence, no doubt, there are various corrugated box styles to choose from, including:

- Regular Slotted Boxes

- Half Slotted Containers(HSC boxes)

- Full Slotted Boxes

- Tab Lock Roll End

- Roll End Tuck Front

- Roll End 3 Flaps Tuck

- Gusset Folders

You can also get your boxes personalized by working with a reliable manufacturer, such as Pack Legacy.

What to Consider When Choosing Corrugated Boxes?

To choose and get the right corrugated boxes, your business needs to consider some essential factors, such as:

- The type and weight of products you need to pack

- Shipping and handling conditions

- Environmental impact\

- Customization possibilities

- Storage and handling regulations

- Costs

Most importantly, you should measure your box dimensions accurately to ensure your product fits perfectly in a corrugated box.

Summing Up

Indeed, corrugated boxes are the most popular packaging choice preferred by businesses across various industries. From simple retail boxes to delivering products, many brands rely on corrugated for their packaging needs. Hopefully, the comprehensive guide above will help you learn more about selecting the proper corrugated packaging for your business.

FAQs

What is a corrugated box?

A sturdy corrugated box is made from corrugated cardboard, which is renowned for its exceptional durability and flexibility.

What is the difference between cardboard and corrugated cardboard?

Cardboard is essentially a thin, pasteboard material made from heavy paper pulp or paper stock. On the other hand, corrugated cardboard consists of three layers — a fluted filler (corrugated medium) sandwiched between flat liner boards.

What is a flute in corrugated packaging?

Flutes in a corrugated box will appear as the wavy lines sandwiched between two flat layers of linerboard.

What are the benefits of using corrugated boxes?

Corrugated boxes offer numerous benefits, including enhanced product protection, lightweight design, customization options, sustainability, and cost-effectiveness.